Sampling and Sampling Plan

Sampling and Sampling Plan

A guide to sampling and sampling plans

March 30, 2021

By Michelle Milne

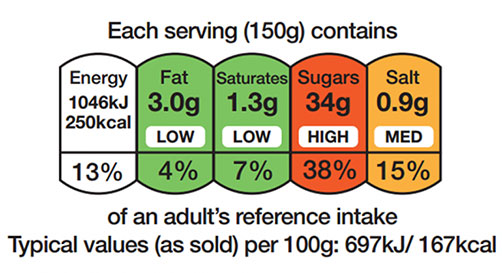

When designing a sampling and analysis plan it is vital that producers identify the information they expect to gain from the plan. For example, to produce a compliant nutritional label that represents the average nutritional data of the whole population of the product on sale. The plan must give an average value to be used on the label taking into account the variability of the product. Robust average nutritional data will help the producer defend a challenge to the label. For example if an independent sample of fish tested by trading standards indicates a 20% variance between the label fat value and the reported result. Evidence of a 25% variance in fat levels over the year would adequately explain the anomaly.

The adequacy and condition of the sample or specimen received for examination are of primary importance. If samples are improperly collected and mishandled or are not representative of the sampled lot, the laboratory results will be meaningless. When submitting a sample for analysis the producer is submitting a small sample of the total population as an estimate of the average of the whole population. In the same way that no two humans have the same fat, protein and moisture ratios the same applies to fish, sheep, pigs or cows etc. A large number of factors can affect the nutritional values of a product. Below is a list of just some factors.

Ingredients:

- Seasonal Variability

- Source Variability

- Supplier Variability

- Batch Variability

- Homogeneity

Production:

- Ingredient Weight Variability

- Portion Weight Variability

- Cooking Variability

- Line Variability

- Batch Variability

- Homogeneity

- Sampling Variability

Testing:

- Sample Preparation Homogeneity

- Analytical Uncertainty

Know your product, decide which of the above factors most affect your product and tailor sampling plan to match, compare results from batch to batch or the start, middle and end of a run. From these multiple tests build a picture of the variance in nutritional components such as fat, protein and salt so that all factors influencing the inherent variance of your product are incorporated into a robust nutritional label. Thus providing consumers with the most accurate information about your product.